WHAT WE DO

Handerek Technologies has created a groundbreaking patented technology which chemically recycles waste plastic into feedstock to make clean recycled plastics or to be used as low-carbon alternative fuels.

We aim to become the global standard in plastic to fuel technology and have a significant positive environmental impact by maximizing waste recycling.

Grand Prix winner

of major innovation and technology fairs

Handerek Technologies sp. z o.o

realizuje projekt dofinansowany z Funduszy Europejskich

„Wdrożenie na rynek innowacyjnej technologii do produkcji niskowęglowych produktów węglowodorowych przeznaczonych dla przemysłu petrochemicznego i chemicznego”.

Celem projektu jest wdrożenie na rynek innowacyjnej technologii do produkcji niskowęglowych produktów węglowodorowych (średniej frakcji olejowej „HAT-OIL“, oraz lekkiej frakcji benzynowej HATLIGHT) przeznaczonych dla przemysłu petrochemicznego i chemicznego.

Dofinansowanie projektu z UE: 22 111 554,85 PLN

State-Of-The-Art Technology of

Waste Plastics Conversion Into Fuels

PLASTIC WASTE

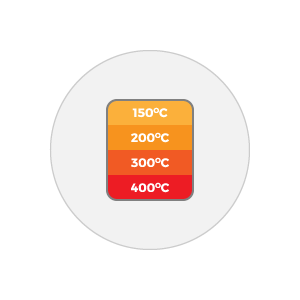

CRACKING

HYDROGENATION

ISOMERIZATION

FRACTIONATION

REFINED FUEL

PLASTIC WASTE

CRACKING

HYDROGENATION

ISOMERIZATION

FRACTIONATION

REFINED FUEL

1 KG WASTE PLASTICS = 1 L FUEL

Benefits:

- End product is fuel of quality compliant with EU standards:

- diesel

- gasoline fraction

- jet fuel fraction

- Process is commercially attractive without external subsidies

- Technology generates revenues thus minimizing overall waste management cost for local governments and communities

- Positive environmental impact

Innovative technology:

- Unique technology resulting directly in engine fuels meetings the requirements of EU standards and ready to use or sale

- Designed to operate in a continuous mode

- Process runs under atmospheric pressure

- Process is energy self-sufficient providing gas and fuel used to operate it

Other

advantages:

- Effective plastic waste management and recycling

- Reduction of plastic waste in landfills and environment

- Respect for natural resources of raw materials

- Increased energy diversification

- Reduces import of crude oil

- Fuel produced with CO2 emissions lower than that of production from crude oil